rexresearch1.com

» NELSON, Robert : The Electrical Tickle -- An introduction ElectroCulture -- Faster growth and maturation and ripening, Larger, taller trees, increased yields, better flavor and nutrient content, increased disease resistance, improved absorption of fertilizer...

» AKIMOV, Anatoly : Torsion Field Generators -- Rejuvenation, stress reduction, plant growth stimulation, & metal modification.

» BINJIANG, Liu : Electroculture & ElectroHusbandry -- Increase yields, reduce pesticides, protect vs swine flu, &c; articles & 5 patents.

» CHAPIN, Richard : Interstellar Light Collector -- Focused moonlight / starlight improves seed germination, etc.

» CHREE, C. : An Electroculture Problem

» CHRISTOFLEAU, Justin : ElectroCulture ~ Patents

» CROSSE, Andrew : Memoirs ~ Phenomenal results, accelerated growth, increased yields.

» DUDGEON, E.: Growing Crops and Plants by Electricity! Details practical methods of electroculture.

» EBNER, Guido : Primeval Code -- Electrostatic fields evoke ancient DNA characteristics, produce plants & animals with increased vitality & yields.

» Electro-Culture # [ 1 ] [ 2 ] [ 3 ] -- Scans of early 1980s 'InFolios' ( Information Folios ) about EC.

» Electrolyzed Water ~ Disinfect with electrolyzed water.

» FANTUZZI, . G: Energy Accumulator ~ Geometric forms + Cu coils + Orgone = accelerated germination, oscilloscope-detectable electrical wave, mummification, & activation of Geiger counter.

» GUASCO, Roger : Theta Amplifier -- "Green Ray" generator stimulates plant growth, improves health.

» HULL, George : Electro-Horticulture

» JOHNSON, James : Dipole Resonance Mutation -- Select frequencies in electrostatic field effect phenomenal chemical changes: food preservation, catalysis, electroculture &c... ( GB417501 : Process for Altering the Energy Content of Dipolar Substances )

» JORGENSEN, I.: The Electroculture of Crops ( Scientific American 1918 )

» LAEMSTROM, Selim: Electricity in Agriculture & Horticulture ~ 1904 Cornell Univ. publication detailing results of experiments: over 100% increase w/ others.

» LAEMSTROM, S.: Experiences sur l'Influence de l'Electricite sur les Vegetaux ~ A pioneering text in the field of Electroculture

» LEE, Jimmy: Ion-A-Gro -- Solar-powered plant ionizer increase yields 30%++

» LEVENGOOD, William: Electroculture ~ Sophisticated methods determine seed viability, improve germination & breeding.

» NELSON, Robert: Tree-lectricity -- ElecTreecity -- The Next Bigly Thing ! How to bioharvest electricity from trees, receive-transmit w/o interference, & more...

» POHL, Herbert : Electroculture

» POHL, H. : Electroculture for Crop Enhancement by Air Ions

» RAVATIN, Jacques: Activators ~ Smaller, more powerful versions of Sprink Activators: displacement of magnetic fields, 10%+ reduced gravity, use 50% less fuel, increased solubility, improved plant growth, eliminate catalysts in reactions.

» SQUIER, George: Trees as Antennas ~ Trees can be used as antennas for static-free reception and transmission at any wavelength.

» STERNHEIMER, Joel : Plant Protein Music -- Increase plant growth, milk production, yeast activity, healing.

» Tourmaline ~ Patents & articles re: "Electric Stone" - batteries, electroculture, healing.

» Van TASSEL, George : When Stars Look Down

» WADLE, G.: Tree Electricity ~ Low voltage bioharvester replaces batteries.

» WHEATON, Frederick: Effects of Various Electrical Fields on Seed Germination

» 1er Congres d'Electroculture ( 1912 )

» Yamaguchi, Frank, et al. Electroculture of Tomato Plants in a Hydroponic Greenhouse

» New Age Science Journal ( June 1976 ) : Magna Culture

http://10.184.80.155/www.sciteclibrary.ru

SciTecLibrary - Technology Database

Presowing Treatment Of Seeds By A Pulsed Magnetic Field: A New Technique In Crop Production

The new technique of presowing treatment of seeds is based on their irradiation by a pulsed magnetic field. It speeds seed germination, stimulates further plant growth, and increases grain and vegetable yields. The method is environmentally clean and has a low energy consumption.

Highly efficient installations have been developed for the large-scale use of the technique of the presowing pulsed magnetic field treatment (PMFT) of seeds in crop production. The method has been tested with success in the Central Black-Earth Area of Russia over the past five years. The mutational variability of plants grown with the use of presowing PMFT did not exceed the natural background for conventionally grown plants.

The stimulating effect of presowing PMFT is manifested in a change of the thermogenesis parameters at early stages of seed germination. The time-dependences of the temperature changes of the germinating seeds indicate that presowing PMFT shortens the duration of physico-chemical thermogenesis and increases the amplitude of the thermal fluctuations of biological thermogenesis.

The PMFT installation consists of a small generator of electric pulses and a source of a magnetic field (an operating chamber in the form of a solenoid coil).The seeds are subjected to the PMF treatment as they are poured through the operating chamber. The installation, intended for use in production conditions, has the following technical specifications:

power supply ................................................ 220V, 50Hz or 110V, 60 Hz

intake power ................................................. 50 VA

capacity ...................................................... 10 tons per hour

operating chamber dimensions:

diameter........................................... 200 mm

length ............................................... 500 mm

weight ............................................... 6 kg

duration of continuous operation -- unlimited.

The PMFT-induced effects are very sensitive to the parameters of the magnetic pulses and operating mode. The PMFT parameters and magnetic treatment modes constitute the know-how of the technique.

The proposed method of PMF seed treatment stimulates seed germination and can therefore be used to increase the field germination rates of seeds and, hence, their price. The treatment suppresses the spread of root rot and is an alternative to fungicide treatment of the seeds. Presowing PMFT enhances plant vitality and yield, the treatment being most effective on fertile and fertilized soils.

The proposed technique can also be used in the food industry, specifically to hasten barley seed sprouting in beer production. The R&D involved in the technique has been completed, and it can now be employed on a large scale. The method has been successfully tested on farms in the Voronezh, Lipetsk, Nizhny Novgorod, and Moscow regions. Highly efficient installations have been developed to implement the method.

Popular Science

(November 1940)

"Fruit Grove Protection System"

DeLand's "Frost Guard"

"Electricity Controls Tree Growth"

"Shocking Weeds to Death"

Electricity as a Tree Pest Cure

US2010281771 -- Disease Control Method and Disease Control Device

Abstract -- A disease control device has light emitting diodes (D1 to Dn) emitting green light and a controller (2) controlling a drive circuit (1) for turning on the light emitting diodes (D1 to Dn). The drive circuit (1) is controlled by the controller (2) to cause the light emitting diodes (D1 to Dn) to emit green light to irradiate plants with the light. The irradiation with the green light enhances resistance of the plants against diseases.

WO2010066733 -- METHOD AND DEVICE FOR COMBATING PLANT PESTS

Cited documents: WO2006021225 // US5968401 // DE19852381 // US4434345

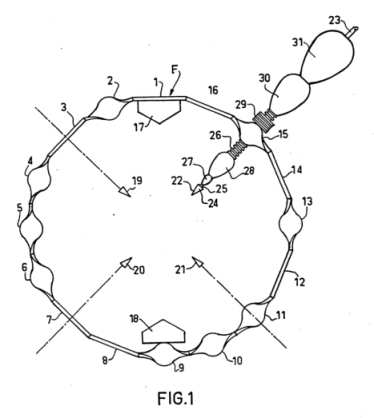

Abstract -- The method serves for combating plant pests, in particular tree pests, by means of microwaves which generate a concentrated energy flux of high frequency which generates in the pests an overheating of the water-containing cells. The device has therefor generators (1) for generating microwaves of high frequency for combating plant pests. When used on trees, the generators (1) are arranged in a ring shape in such a manner that the microwaves are directed toward a common center

DE202005015561 -- System for nourishing and growing plants in pots comprises playing music to them

Abstract -- The system for nourishing and growing plants in pots (1) comprises playing music to them, e.g. from an earpiece (2) connected to an mp3 player (4).

IL31428 -- Electroculture

100 lb magnetite ( Fe3O4, 100-mesh or smaller ) / acre with applied electrostatic charge frpm 440-V DC electromagnetic coil : resistivity to subfreezing temperatures & insects, increased fruit size, yield, growth rates, increased number of crops/year.

FR2586892 -- Device for Electroculture

Cited documents: FR2355441 // FR649730 // FR734980

Abstract -- Device for electroculture with minimum two metal grates or plates (2, 3) arranged in parallel in the cultivated soil (4), in a north-south direction, and with a voltage source (6) with an antenna (7) and that supplies the metal grates (2, 3) with an electric current of natural origin, device for electroculture characterized in that the aforesaid voltage source (6) consists, on one hand, of the antenna (7) for collecting atmospheric electricity and, on the other hand, of one or several photocells (8).

FR2798252 -- Device for germination and treatment of seeds, or plants and other vegetables by high frequency pulsed electromagnetic waves

Abstract -- The device has an electronic circuit (2) which produces high frequency pulses. The circuit (2) is connected to an electro-magnetic field emitting aerial (3). the whole being connected to an electrical supply. The device can be fitted into a seed box, see Figs 1,2, for seed germination or attached to a row of vines where the support wires act as aerials.

MD3790 -- Process for treating corn seeds with reduced germination

Abstract -- The invention refers to agriculture, particularly to a process for presowing treatment of corn seeds. The process for treating corn seeds with reduced germination includes their electromagnetic irradiation with millimetric waves having a length of 5,6 mm, at the power density of 6,6 mWt/cm2 and the exposure of 2 min. The result of the invention consists in increasing the growth and germination energy of seeds.

RU2321981 -- METHOD FOR DESINSECTION AND DISINFECTION OF MATERIALS OF GRAIN ORIGIN

Abstract -- Method includes creation of re-circulating gas stream in discharge chamber, injection of UHF energy, creation of plasma in chamber volume and letting material being processed through the chamber in form of free-falling stream. The UHF energy for creation of plasma is injected in impulse or in continuous modes in form of three electromagnetic waves, two of which have orthogonal linear polarization, which is perpendicular to the discharge chamber axis, and third wave has axial component of electromagnetic field, and the material is additionally affected by modulating at least one electromagnetic wave with impulses with frequency of repetition within ultrasonic spectrum. Duration of impulses equals 1-5 microseconds. Also, modulation frequency changes continuously in aforementioned ultrasonic spectrum with period of 0,01-0,02 seconds, and constant electric current is additionally let through plasma equipment. ^ EFFECT: prevented infection of grain by barn billbug, suppressed bactericide infectiousness and increased germination capacity of grain.

CN201018769 -- High voltage pulse constant magnetic field seed instrument

Abstract -- A seed instrument with high voltage pulse static magnetic field, the positive electrode and negative electrode output ends of the high voltage pulse signal power source device [1] are respectively connected with two Helmholtz coils [3] which are similar in structure, uniform in size by power source cord [5]. A pulsed magnetic field or a uniform magnetic field can be formed between the two Helmholtz coils. The two coils [3] are clipped by two circular insulating boards [2] which are fixed by a bolt [6]. The coil [3] comprises a silicon steel sheet core [4] which is a cylinder, enamel wire layers [7] and cyan-shell papers [8]. The enamel wire layers [7] are isolated by the cyan-shell papers [8] and winded on the exterior circle of the silicon steel core [4]. The utility model is simple in structure, feasible in maneuverability, lower in cost and can create a manually controlled electromagnetic environment for plant growing which can improve the germination effect of the seed, make the seeding emergence stronger, shorten the growth period, enhance the antiviral ability, make the branches more leafy and the fruit bigger, therefore attaining the purpose of promoting plants in high quality and yielding.

EP1676815 -- Electromagnetic treatment process for liquids

Abstract - The electromagnetic fields emitted from reels and antennas placed center of a tank, basin or ground water level and show tension, current, pulsation, signal shape and resonance frequencies of chemicals. The characteristics of the liquid are used for acceleration of germination, plant growth, diseases resistance, eutrophication and oxygenation of water, inhibition of microorganisms, separation of solid/liquid, decantation, filtration, centrifugation and aggregation of colloids. The chemicals are oxidizing, coagulating and flocculating agents, nutrients and pesticides. An independent claim is also included for application of electromagnetic process.

GB1271545 -- APPARATUS FOR MAGNETICALLY TREATING SEEDS

Abstract --Treating seeds to increase germination speed. The germination speed of seeds is increased by moving the seeds in a helical path through a magnetic field, or other field produced by a source of electric, magnetic or electromagnetic energy. As shown, a screw conveyer 20 conveys the seeds from an inlet chamber 16, which is supplied by a hopper 10 via a control slide 14, to an outlet chamber 24, the seeds being caused by the centrifugal force to move in a helical path along the inside wall of a plastic tube 22 past an electromagnet 38 surrounding the tube, so as to be subjected to a magnetic field while the seed is both moved in a helical path and is at the same time rolled to expose several surfaces of the seed to the field. The treated seeds are collected in a collector 26. The electromagnet 38 may be replaced by electric field generating means, or by X-ray, high frequency, microwave or other electromagnetic field generating means.

JP2004089207 -- METHOD FOR SUPPRESSING DECREASE OF GERMINATION RATE IN STORAGE TIME OF PLANT SEED

Abstract -- a method for suppressing decrease of germination rate in storage time of plant seed. ; SOLUTION: The method comprises storing the plant seed under a condition of exposing the seed in an electromagnetic field of 50-60 Hz frequency so as to suppressing decrease of the plant seed germination rate under a storing condition of a high temperature and a high humidity.

JP2004135638 -- METHOD FOR SUPPRESSING GERMINATION OF GARLIC

Abstract -- PROBLEM TO BE SOLVED: To solve the problem of the difficulty in year-round planned shipping of garlic caused by the sudden retire of a germination suppressing agent represented by 39% solution of maleic hydrazide for suppressing the germination of garlic. ; SOLUTION: The sprouting part and the root part of a garlic are subjected to predrying treatment at >=30[deg.]C for >=3 days after harvest and irradiated with continuous or pulse electromagnetic radiation to suppress the germination of the garlic. The germination of garlic is suppressed relatively easily at a low cost simply by treating the sprouting part or the root part of garlic with electromagnetic wave harmless to food or with ethyl alcohol known as a safe additive. Furthermore, the germination suppressing treatment of garlic is carried out by specifically combining the hitherto separately performed dry-heat treating storage with the cold storage and finding the optimum storage condition.

CN1383710 -- Electromagnetic-field plasma seed processing machine

Abstract -- In the electromagnetic field and plasma seed processing machine, the radiation chamber has inlet in the upper part, outlet in the lower part and plasma generator connected to electrical controller inside it. The plasma generator is a glass tube filled with mercury vapor and has wire connecting ends at two ends. The present invention has simple structure, is easy to operate, has powerful bacteria and virus killing effect and can activate the inner growth genergy of seeds to result in raised germination potential and germination rate of seed and raised yield and nutritive components of crop.

RU2185714 -- SEED TREATMENT METHOD AND APPARATUS

Abstract -- Method involves exposing seeds to electromagnetic microwave field while subjecting seeds to turbulent mixing in cavity resonator with mechanical ventilation system; additionally exposing seeds to electromagnetic field of millimeter wave band. Exposure to said fields is performed in cyclic periods at suspended state of seeds. Apparatus has cavity resonator mounted on hollow axle shafts for rotation. Paired opposite ridges are arranged inside cavity resonator. Axle shafts are equipped with vent channel and microwave emitter connected to microwave generator. Apparatus is further equipped with millimeter band wave generator and related emitter, and with control unit connected to both generators, mechanical ventilation system and cavity resonator rotational drive. Method and apparatus are used in forestry and agricultural enterprises for presowing seed treatment. EFFECT: increased efficiency and improved lodging resistance of sprouts at early germination stages.

RU2179792 -- SEED TREATMENT METHOD

Abstract -- Method involves prior to sowing, exposing seeds to electromagnetic field with phase-modulated vibrations of extremely low band for 40-60 min at field strength of 120-1,400 A/m. Method is used for presowing treatment of farm crops. EFFECT: increased seed germination and improved efficiency.

RU2175826 -- METHOD FOR TREATING SEEDS

Abstract -- Method involves treating seeds with electromagnetic frequency-modulated oscillations field in extremely low frequency bandwidth before seeding during 40-60 min under field intensity of 120- 1400 A/m. EFFECT: improved seed germination.

RU2134944 -- METHOD FOR TREATING AGRICULTURAL CROP SEEDS

Abstract -- Method involves exposing seeds to low-frequency electromagnetic field with following treatment with red laser radiation. EFFECT: increased germination of crops by bioresonant presowing stimulation of seeds.

DE19605650 -- Treatment or stressing of biological substances with microwaves in presence of water vapour

Abstract -- A method extracts materials from biological substances and may be used to treat seeds and propagating materials to kill harmful micro-organisms. The treatment zone is irradiated by oscillatory electromagnetic energy at microwave frequencies, in the presence of steam or a mist of water vapour. The energy field is homogenised, and controlled to keep the material above a minimum specified temperature, and preferably evened-out closely above the incipient dew point. Also claimed is use of the method for controlled stress induction in seed and propagation material for limited, targeted reduction of germination potential and/or growth energy and vitality.

BG97028 -- METHOD FOR PRESOWING CULTIVATION OF TOMATO SEEDS

Abstract -- The invention is related to a method in which, by single effect on the seeds, their germination, and consonance and dynamics of springing up is increased. It includes the formation of a product layer of seeds up to 12 mm thick which is irradiated by electromagnetic (CB4) waves at 2450 MHz, 150 W at 15% and at exposure time from 210 to 820 sec. or power 300 W 10% at exposure time from 45 to 130 sec. The seeds can be packed or unpacked, with moisture content 7.5-8.5% and germination (estimated) over 85%.

CN2122006 -- DIELECTRIC SEEDS GRADER

Abstract -- The utility model relates to a dielectric seeds grader through which the seeds can be graded and separated according to the activity of the seeds. The utility model is characterized in that the seeds are scattered on a dielectric roller whose surface is wound with a conducting wire through an electromagnetic vibrator and a seed guiding sliding plate; the conducting wire is connected with an alternate current voltage regulator through an electric brush, and is supplied with the alternate current which is from 1000V to 5000V. The surface of the roller grades the seeds having different activities according to the dielectric property of the seeds. The seeds grader using the dielectric roller as a grading component has the advantages of high grading purity and low energy consumption; the seeds can not be damaged; the seed germination rate can be improved during grading.

FR2580897 -- Method and device for a biophysical treatment unit with resonance reagents intended to optimise and accelerate the processes of plant germination and growth

Abstract -- The reagent in the device is a colloidal fluid with ferromagnetic properties, receiving high energy plasmas by means of a pulsed wave generator, in a magnetic field, together with highly dilute solutions of essential oils incorporated in the treatment water, this water passing into a full-wave AC and DC electromagnetic field, then being treated using an electrode connected to a multi-oscillatory high frequency generator with an electromagnetic field being superimposed on the AC electric field, equipped with a flexible plate multiple capacitor containing a biological dielectric, also connected to a pick-up antenna comprising a so-called exterior antenna with 12 horizontal elements terminating in dishes and fixed onto a support insulating them from each other and a so-called interior antenna made of vanadium,; connected separately by means of a 15-core shielded cable (each core being about 1.5 cm<2>), to the flexible plate multiple capacitor and to the pick-up electrodes, one of which is also in the capacitive return circuit loading the water treatment reservoir, as well as transmitters of high energy fields comprising a double spiral antenna efficiently transmitting a very high level of energy per square centimetre connected to an electronic oscillator. Designed particularly for the faster production of commercial plant products in agriculture.

GB417501 -- Process for altering the energy content of dipolar substances

Abstract -- Changes in the energy content of dipolar substances are produced by exposure to a concentrated electromagnetic field having one or more frequencies corresponding to wavelengths between 3 mm. and 6 metres approximately and equal to characteristic periods of the substances treated. Germination of seeds may be accelerated. Bean seeds previously swollen and exposed for 30 sec. to suitable fields germinate twice as fast as untreated seeds... The germination of seeds is accelarated by exposure to a concentrated electromagnetic field having one or more frequencies corresponding to wave lengths between 3 mm. and 6 meters approximately and equal to characteristic periods of the substances treated. ..According to an example, bean seeds previously swollen are treated for 30 seconds at 35 DEG C. with a field comprising wave lengths of 28 cm. and 87 cm. In four weeks they grow twice as much as untreated seeds...

EP0459540 -- Method and equipment for accelerating the growth of, and developing better vital qualities in, vegetable organisms

Abstract -- For accelerating the growth of, and develop better vital qualities in, vegetable organisms, these latter are submitted to the action of a magnetic field. According to the method, a polarized pulsating electromagnetic field is caused to act according to different extents, generally correlated with one another, onto the cultivation earth, the seeds, the plants and the irrigation water. The equipment essentially comprises solenoids subjected to pulsating currents and arranged within units (2) for the treatment of earth and of plants, units (20) for the treatment of water, and units (3) for the treatment of seeds.

EP0039163 -- Method and means for electromagnetic stimulation of a vegetative process

Abstract -- The invention contemplates method and apparatus for altering the growth behavior of living plant cells by inducing voltage and concommitant current pulses of specific time-frequency-amplitude relations therewithin.

RU2095966 -- METHOD FOR PROMOTING WOODY PLANT GROWTH

Abstract -- Method involves exposing tree trunk and/or skeletogenous branches to magnetic field created by mixture of ferromagnetic powder and plastic substance. Powder content is 30-50% by weight. Effect: Increased efficiency in promoting plant growth and simplified method.

The proposed invention relates to the field of forestry and can be used to stimulate the development of woody plants.

The use of the proposed technical solution will significantly reduce labor costs for stimulating the growth of woody plants.

US3935670 -- Apparatus for Selectively Applying Electrical Current to Plants

Abstract ~ Apparatus for destroying selected plants by the application of electricity thereto. A source of high-voltage electrical current is mounted on a moveable platform, and a grounding wheel or the like is provided for insuring safety of the apparatus by grounding various electrical source components. A conductive tip portion of a non-conductive staff member may be connected to the source of current by a cord, and an operator controlled switch in a secondary control circuit is mounted on the staff member. The switch is normally open so that the conductive tip portion will not be energized should the operator release his grip on the staff member. By actuating the switch and bringing the tip portion into mere touching engagement with a plant stem, plant destruction may be effected.

US3940885 -- Process and Equipment for Treating Seeds and Product Thereof

Abstract ~ Seeds are subjected to microwave energy and a coolant gas, then subjected to a partial vacuum to stimulate growth and stabilize such stimulation. Seeds so treated have superior growth characteristics and are more resistant to disease and weather hazards. Apparatus for effecting this process is also disclosed.

US4007794 -- Top Desiccation of Crop Plants

Abstract ~ The above-ground growth of potatoes and like root crops are contacted with high voltage electricity several days prior to harvesting, the electricity desiccating the above-ground portion of the crops while not harming the tubers. A no-load voltage of about 20 kv with an energy density of about 11-15 kw/foot of width treated is effective. Low-bush blueberries, and like perennial crops, are pruned by contacting the above-ground growth thereof with electricity. Pruning, in the case of blueberries, is most effective when done approximately every other year in the case of blueberries, a no-load voltage of 10-20 kv with an energy density of about 2-3 kw/foot of width treated being effective...

The invention relates to a method of killing mature root crop tops prior to harvesting, and to a method of pruning certain perennial crop plants, with minimum adverse impact on the environment. In the past it has been proposed to kill plants with electricity, as shown in U.S. Pat. Nos. 2,007,383, 2,607,165, 2,632,285, 3,543,488, and 3,559,337. It has not previously been recognized, however, that certain root crops can be contacted with electricity to destroy the above-ground portions thereof while not adversely affecting the tubers -- the crop portion -- thereof. This has been recognized according to the present invention, however, and may be utilized to facilitate the harvesting of potatoes, beets, carrots, onions, and the like. According to the present invention, some time before harvesting, after the crops to be harvested are substantially mature, the above ground growth of the crops is contacted with electricity from a high-voltage source, which causes desiccation thereof; for instance for potatoes, the above ground growth is contacted with electricity from a 20 kv source about 10-20 days prior to harvesting, and by the time for harvesting the skin of the potatoes has become more firm, the potatoes are not subject to disease (i.e. leaf roll), and harvesting thereof with conventional equipment is greatly facilitated.

In the past, it has been known to kill the above-ground growth of some root crops -- i.e. potatoes -- prior to harvesting to facilitate the harvesting and firm the skin thereof, but past methods have had a number of drawbacks. For instance, when conventional chemicals are used to kill the above-ground growth, they can and do leave residues which might migrate to the food portion of the crop, and in any event are retained in the soil to some extent and can be assimilated by the next year's crop; if the chemicals are applied too closely to a time when it rains, they may be washed off before they can be effective for killing the above-ground growth and thus a complete wasteful repeat of the application is necessary; dense foliage is not easily penetrated; also; the chemical treatments are often temperature dependent which means that it is not always possible to apply them at the optimum time, and therefore optimum harvesting conditions may not exist. Roto-beating -- that is, actual physical destruction of the above-ground growth -- also is practiced in addition to or in place of chemical application. While roto-beating avoids some of the problems inherent with chemical treatment, it is fairly energy intensive, and is not as completely successful as is the chemical treatment.

It has also not been previously recognized that certain perennial crops -- such as blueberries -- can be pruned with the application of high-voltage electricity, but not destroyed. Conventional proposals for the application of electricity to plants, such as the patents mentioned above, do not recognize that a crop plant may not be killed but merely the above-ground growth thereof destroyed by the application of electricity. According to the present invention, blueberries and like perennial crops, may be treated by the application of electricity -- from a 20 kv source, for instance -- to the above-ground portions thereof every other year to prune the bushes and thereby encourage future growth. Conventionally, pruning of blueberry bushes on a commercial scale is accomplished by burning off of the plants with oilfired burners. While this effectively prunes the plants without serious damage to the root systems, it also destroys much of the organic material in the soil, and is fairly energy intensive. ...it has been found that 20 kv (no load) appears to be an ideal voltage for effecting desiccation of the above-ground portions of the crops, while not adversely affecting the root, food portions thereof. An effective energy density of about 11-15 kw/foot width of crop being treated normally results when such a no-load voltage is being used. While 20 kv and an energy density of 11-15 kw/foot have been found to be workable values, the range of each can vary widely and still be effective for accomplishing the desired result. Any voltage and energy density that results in the application of about 250 milliamps or more to the above-ground stems of root crops (i.e. potatoes) is believed effective. A maximum on the voltage and energy density would be that which would apply so much current that the root portion of the crop was adversely affected; however, there appears to be no adverse effect whatsoever when 12 kv with an energy density of about 11-15 kw/ft is utilized.

The following table gives a summary of actual test results for the method of top killing of root crops according to the present invention. Katahdin potato vines in Maine were treated approximately 21 days prior to harvesting, the potatoes being harvested approximately 4 months after planting, and the vine kill rating of the method according to the present invention was determined one day prior to harvest. The kill rating code for the below (and the succeeding) table is 1=no or poor kill of leaves and stems, 2=90% of leaves but poor stem kill, 3=100% of leaves and 40% of stems killed, 4=100% of leaves and 70% of stems killed, and 5=100% of leaves and stems killed. By dragging behind a tractor six 24 inch vertical chains (covering a 16 inch horizontal band) which were electrically energized with AC current, the following results were obtained:

TABLE A __________________________________________________________________________

Energy Voltage Density (no load) Speed Current Amps (approx. Vine Kill (kv) (load) M.P.H. (under load) Direction kw/ft) Ratings __________________________________________________________________________

No treatment (control) 1.00 20 :12.5 0.5 1.14 one 11 3.65 20 :12.5 0.5 1.14 two 11 4.05 20 :12.5 1.0 1.14 one 11 3.47 20 :12.5 1.0 1.14 two 11 3.87 __________________________________________________________________________T

here was slight regrowth on all plots, however, this regrowth may -- it is believed -- be avoided to a large extent by harvesting closer to the date of treatment with the electricity. Treatment with electricity should precede harvesting by 10-20 days...

It is noted that the effectiveness of the kill with Dow General and Des-I-Cate may be increased through proper application thereof by adjustment of the differential pressure and water dilution (applied with an F.M.C. sprayer) to 5.0 when the differential pressure and water dilution factors are optimized...

US4020590 -- Apparatus and Method for Exposing Seeds to a Magnetic Field

Abstract ~ Apparatus for magnetically treating seeds comprises a magnet for producing a unipolar magnetic field, an enclosed generally cylindrical housing having a closable access opening therein in which said seeds are placed for treatment, drive means associated with the housing for rotating said housing and imparting rolling and tumbling motion to the seeds within the housing, the housing being disposed with respect to the magnet such that the seeds move through the magnetic field as they roll and tumble. By magnetically treating the seeds in a unipolar magnetic field while rolling and tumbling the seeds, the characteristics of plants grown therefrom are favorably altered.

US4047326 -- Vascular Contact Rotating and Stationary Abrading Electrode Devices for Electric Weed Killing

Abstract ~ Undesirable vegetation or weeds are destroyed by electrical current conducted therethrough by prolonged contact with electrodes. Internal plant tissues of the vegetation are exposed for electrode contact by removal of electrically resistant external layer portions through abrasion of the plant stems or stalks along a path of movement of the apparatus to reduce the electrical energy requirements for plant destroying purposes.

US4092800 -- Vegetation Control

Abstract ~ Microwave transmitters generate electromagnetic energy at a desired frequency in the range of from 300 MHz to 300 GHz. Energy derived from the microwave transmitters is coupled into a waveguide for transmission to an energy radiator coupled to the waveguide. The energy radiator, waveguide and microwave transmitters are vehicle mounted such that the radiator is made to pass over areas in which it is desired to control vegetation. Vegetation, including seeds, in the path of energy emitting from the radiator absorbs the energy from the field resulting in internal changes in the plant or seed causing death or debilitation of the vegetation or seed.

US4094095 -- Method and Apparatus for Using Electrical Current to Destroy Weeds...

Abstract ~ A method and apparatus for destroying weeds growing in and around crop rows without destruction of crops growing therein. A plurality of electrically conductive spring members are disposed in a generally horizontal plane and connected to a high voltage source of electricity. The spring members have a spring constant such that relatively stiff crops plants will deflect the spring members while relatively flexible weeds will not deflect them. Substantially all of the plants in and around the crop rows are contacted with current-carrying portions of the spring members by moving the spring members relative to the crop rows parallel to the crop rows. A larger dwell time of contact is provided between the spring members and the relatively flexible weeds then the dwell time of contact between the spring members and the relatively stiff crop plant so that the weeds receive sufficient electrical energy to result in destruction thereof, while the crop plants do not receive sufficient electrical energy to result in destruction thereof. The difference in dwell time is provided by forming each spring member so that it has one end connected to a supporting member and the first portion extending from the connected end making a first angle .alpha. with a line along the direction of movement of the spring member, and having a free end with a second portion adjacent the free end making a second angle .beta. with a line along the direction of movement of the spring member, the angle .beta. being substantially greater than the angle .alpha., and by disposing the connected end of the spring member between crop rows while the free end extends into a crop row during movement of the spring member to affect contacting.

US4177603 -- Plant Destruction Using Electricity

Abstract ~ A machine and method for destroying plant growth. A specialty application is provided for plant growth around and between railroad tracks, and a general description is provided for preventing damage to the high voltage source of electricity used for the plant destruction, and for minimizing the number of fires started in dry material accessory to plant destruction. A vehicle with a high voltage electricity source is mounted on railroad tracks, with wheels of each wheel set for the vehicle being electrically isolated, and the high voltage source being grounded through one of the wheels. Special plant contacting devices comprising rounded end generally cylindrical contacting members are provided. The current output of the high voltage source is limited to prevent damage to the high voltage source, and the no-load voltage of the high voltage source is held to generally the same level as the full-load current limited voltage to minimize the number of fires started by the plant contactors.

US4188751 --Magnetic Seed Treating Device

Abstract ~ A device for magnetically treating seeds prior to planting so as to increase the yield of plants grown from the seeds. The device includes a tubular member provided with an internal support for securing a permanent magnet therein so that as seeds are poured through the tubular member, they are magnetically treated. The magnet, which has opposite poles disposed at opposite ends thereof, is oriented with its longitudinal axis extending in the direction of the passage, the passage adjacent the magnet being of substantially annular shape in cross-section whereby a uniform cylindrical shaped magnetic field occupies the annular passage through which the grain must pass. The tubular member has a converging portion in the direction of seed travel so as to provide an area of maximum constriction adjacent the magnet which results in the seeds being funnelled radially inward towards the more concentrated magnetic field closest to the magnet. The converging or constricted portion may be shaped to provide the flow of seeds along streamlines so that the rate of flow is enhanced.

US4198781 -- Plant Destruction Utilizing Electrically Conductive Liquid

Abstract ~ A machine is provided for destroying plants with electricity comprising a tank adapted to hold electrically conductive liquid, an electrode for placing the electrically conductive liquid in the tank at high electrical potential, including a high voltage source of electricity; nozzles for spraying the electrically conductive liquid on plants to be destroyed; and a structure for grounding the high voltage source. Air pressure provided over the liquid in the tank provides the motive force for spraying, and pneumatically operated valves in line with the nozzles are provided for selectively supplying liquid to the nozzles. In this way, there are no moving parts which are electrically charged. Condition-responsive structures, responsive to plant position, are provided for controlling operation of the pneumatic valves, such as air limit proximity switches. The current output of the high voltage source is limited so that damage to the source is prevented, and the no-load voltage of the high voltage source also is preferably controlled.

US4240365 -- Magnetic Seed Planter

Abstract ~ Planting apparatus including a supporting frame adapted to be connected to a tractor or similar vehicle; a seed hopper mounted on the supporting frame for containing a supply of seeds, and seed metering mechanism spaced beneath the discharge outlet of the seed hopper for controlling the movement of the seeds discharged from the hopper on the ground. A magnetic seed treating device is disposed in the path of seeds discharged from the hopper for causing the seeds to pass through a magnetic field to magnetically treat the seeds as the seeds are planted.

US4291125 -- Method for Electronic Control of Infections Using Silver Ions

Abstract ~ A method and apparatus for killing plant and animal bacteria and plant viroids by electrically generated silver ions. The silver ions serve as germicidal agents in infection control and are generated by very slow electrical anodic corrosion of a silver wire located closely adjacent the infection site. In particular, a silver anode and a cathode of non-corroding metal are located in an electrolytic nutrient medium with the silver anode being within five millimeters of the infection site, and a direct voltage is applied to the anode and cathode in a manner passing a positive current in the microampere range into the silver anode causing it to corrode slightly and give off silver ions which produce a germicidal environment about the infection site.

US4302670 -- Electrogenic Seed Treater

Abstract ~ Method and apparatus for treating seeds, such as corn, soy beans and rice, in which the seeds are first coated with a mixture of water and enzyme and then subjected to a series of electrical potentials that causes water, ion particles, and nitrogen components to be impregnated within the seed for the purpose of improving the embryonic and growth potential of the seeds.

US4338743 -- Safety System for Weed Destroying Apparatus...

Abstract ~ Weed destroying apparatus carried on a vehicle has a generator; a step-up transformer having its secondary winding coupled to electrodes for contacting and killing weeds; a programmable semiconductor logic array; a first contactor coupled to an output of the logic array for connecting the generator to the transformer primary winding in the weed killing mode; a second contactor coupled to an output of the logic array for connecting the generator to electrical outlets for supplying electrical power to auxiliary farm equipment in a standby mode; a run/standby switch for providing binary signals to the logic array indicative as to whether the apparatus is to operate in the weed killing mode or the standby mode; a plurality of safety systems each of which has redundant interlock means for preventing an unsafe condition in which high voltage would be a hazard in the weed killing mode and sensing means for providing binary signals to the logic array indicative of whether each interlock means is in the safe condition or an unsafe condition; and a generator frequency interlock for detecting generator frequency in the standby mode and for applying binary signals to the logic array indicative of whether generator frequency is within a predetermined range.

US4338744 -- Safety System for Weed Destroying Apparatus

Abstract ~ A weed destroying system carried on a vehicle and having electrodes for contacting weeds and a high voltage generator and a step-up transformer for supplying high voltage to the electrodes is provided with a tamper-proof safety system having redundant safety interlocks to effectively ground the vehicle and redundant safety interlocks to prevent energization of the generator until the vehicle is traveling at a predetermined speed and which de-energizes the generator if any one safety interlock is bypassed or fails in an unsafe condition, thereby requiring plural simultaneous failures to create a condition that is hazardous to the operator or to a bystander. The safety system also provides immediately-visible warning of the electrical hazard created by the apparatus and provides visual and aural indications to the operator when a safety interlock has been bypassed or is jammed closed.

US4428150 -- Electrode Arrangement for Electric Weed Killing Apparatus

Abstract ~ Apparatus for destroying weeds in and around crop rows has a high voltage source of electricity mounted on a vehicle; a coulter wheel for connecting the high voltage source to the ground; a plurality of weed contacting electrodes carried on the vehicle and insulated therefrom; and a plurality of isolating electrical reactance inductors each of which connects a weed contacting electrode to the high voltage source and limits the magnitude of current flowing through the high voltage source when the electrode contacts a weed to thereby minimize the voltage drop across the high voltage source and maintain substantially constant voltage on the remaining electrodes.

US4633611 -- Process and Apparatus for Disinfecting Seeds

Abstract ~ An apparatus and process for the disinfection of seeds, preferably those of grains, to prevent pathogenic organisms from being planted with the seeds, and to provide reliable disinfection without using toxic agents. The seed is irradiated by low-energy electrons with energy and dosage controlled so that the surface and regions close to the surface are exposed to the radiation with fungicidal effect. A beam of the low-energy electrons is provided by an electron gun aimed at a region within a seed-receiving chamber at which the seeds to be irradiated are caused to intercept the radiation repeatedly and on all sides. The chamber may be at atmospheric pressure or be evacuated, the latter condition requiring vacuum locks at seed inlet and outlet ports of the chamber.

US4680889 -- Process for Treating Plants

Abstract ~ The present invention is a process for stimulating or inhibiting plant growth and includes the steps of applying a plant growth stimulant or inhibitor and subjecting the plant to high frequency sound waves.

US4758318 -- Method for Improvement of Soil

Abstract ~ The molds infesting a given soil are extirpated by the flow of a pulsating direct current of not less than 50 mA to prevent a farm product from diseases causable by the aforementioned molds.

US4785575 -- Horticultural Device for Raising Garden Plants Utilizing Magnetism

Abstract ~ A horticultural device utilizing magnetism for raising plants includes a plate-shaped section in which a fertilizer is imbedded, and a rod-shaped section extending from the bottom side of the plate-shaped section and having a fluid flow passageway, at least a portion of the device having a magnetic property. The rod-shaped section is thrust into soil surrounding a plant until the plant-shaped section contacts the soil surface. The fertilizer carried in the plate-shaped section is gradually dissolved and converted into a magnetized fertilizer solution by watering, the fertilizer solution dispersing itself into the soil through the liquid flow passageway of the rod-shaped section.

US4891317 -- Magnetic Alternation of Cellulose During Its Biosynthesis

Abstract ~ A method of producing cellulose of amorphous character by subjecting cellulose-producing organisms to a magnetic field substantially greater than 0.5 gauss and preferably at least about 500 gauss. The cellulose produced in the presence of a magnetic field is of an amorphous nature with increased water absorptivity and decreased crystallinity.

US4915915 -- Water-Powered Piezoelectric Unit for Producing Nitrogen Fertilizer

Abstract ~ A system for producing nitrogen fertilizer using an electric arc process is described in which the electric arc necessary for the process is generated by piezoelectric elements actuated by a hammer mechanism powered by water pressure such as from a garden hose. The nitrogen oxides produced by the arc discharge are drawn into the water to serve as a source of nitrogen fertilizer. The net result of the invention is that the operator can provide nitrogen fertilizer as he supplies water to the same area. The only inputs to this system are air and a source of water under pressure.

US5060414 -- Phytotoxicity of a Combined RF and Microwave Electromagnetic Field

Abstract ~ A method and device for vegetation control. More particularly a technique of a plurality of steps in the application of electromagnetic fields of two or more selected but different frequencies, at least one in the ratio frequency range being first applied followed by application of others in the microwave region, to the area in which vegetation is to be controlled.

US5077934 -- Method and Apparatus for Controlling Plant Growth

Abstract ~ A method and apparatus for controlling plant growth is provided. The apparatus includes a magnetic field generator for producing a controlled, fluctuating, directionally oriented magnetic field parallel to a predetermined axis projecting through viable plant material. In one aspect, a magnetic field detector measures the magnetic flux density along the predetermined axis. The applied magnetic field may comprise a full-wave rectified signal oscillated at predetermined frequencies to maintain a preselected ratio of frequency to the non-zero average value of the flux density, where the ratio is effective in altering the natural growth characteristics of the target plant material, such as accelerating growth rate. This ratio is maintained by adjusting the frequency of the fluctuating magnetic field and/or by adjusting the intensity of the applied magnetic field after nulling out or measuring and accounting for the local magnetic field in that region containing the target plant material.

US5097625 -- Seeding and Seedling-Growing Sheet and Seeding and Seedling-Growing Method

Abstract ~ The present invention is to provide a seeding and seedling growing sheet and a seeding and seedling-growing method comprising using the sheet, which are to be used for seeding and growing seedling of grain, vegetable, flower and the like, and which are suitable for efficiently seeding at a desirable position and a desirable density with a higher positional precision and for promoting the growth at germination, by employing the seeding and seedling-growing adhesive sheet comprising a sheet support body composed of water-soluble or water-dispersible paper or water-soluble polymer film, an adhesive agent containing a powdery ferromagnetic substance being coated in spots or in stripes on the support body, and by applying the seeding and seedling-growing method comprising using the adhesive

sheet.

US5117579 -- Method and Apparatus for Applying Fixed Nitrogen to Plants

Abstract ~ An electrical ion emitting farming implement to be moved over a field of crop planted in earth for above ground atmospheric treatment of growing plants comprising a frame. A series of bell-shaped members are mounted at spaced intervals on a boom across its transversely extended length and with the bell-shaped members opening in a downward direction toward underlying plants in a field of crops. A wire brush-like ion emitter is centrally mounted in each of the bell-shaped members. An electrical circuit ion generating mechanism operatively connected to the wire brush-like ion emitters for emitting electrical ions in the 30 to 50 KV range through the wire brush-like ion emitters. A power source is provided for energizing the electrical circuit means. A control is provided for activating the electrical circuit means for causing ion emission through the wire brush-like ion emitters upon placement of the bell-shaped members in spaced overhead position relative to the plants being treated. The electrical circuit ion generating means includes a pulsed high output ion generator. The generator has at least of pair of selectable frequencies operable in a range of 90 HZ through 400 HZ. is positioned forwardly of the emitters to be dragged in the earth to complete the circuit.

US5141059 -- Method and Apparatus for Controlling Agricultural Pests in Soil

Abstract ~ A method and apparatus for controlling agricultural pests in soil by the use of microwave energy. By using an agricultural-type implement for the controlled application of microwave energy to the topsoil prior to the planting of crops, germination of weed and other seeds is inhibited and insects are destroyed. Use of microwave energy has no residual effects, thereby practically eliminating any adverse effects on the environment.

US5271470 -- Plow Apparatus and Method Using Acoustics

Abstract ~ The plow apparatus has plow blades to break up the soil in the plowed field. The broken up soil is scooped up with scooper blades by the forward motion of the plow apparatus and then conveyed to rotating tillers. The tillers break up the soil into smaller clumps. The tilled soil is then exposed to acoustical energy provided by acoustical transducers. The acoustical energy is of a sufficiently high intensity so as to kill or destroy weed seeds and insect larvae in the soil. The soil is then returned to the ground.

US5464456 -- Electronic Stimulation of Plants

Abstract ~ The invention relates to the electronic stimulation of plant development. More particularly, it relates to the stimulation of plant development through electrifying the environment around a plant or part of a plant with an electrical field, preferably a pulsed field. The present invention also relates to an electronic method of stimulating the active membrane transport systems of growing plants and harvested plant products in order to promote growth and extend the shelf life of harvested material. The invention is of particular interest as it relates to shipment and marketing of cut flowers, greens and trees and more particularly to methods and apparatus for handling, shipping, and marketing of cut flowers.

US5600918 -- Apparatus for Killing Weeds

Abstract ~ Apparatus which comprises a housing having a compartment and a shaft, a piezoelectric crystal captured in the compartment of the housing and an actuator assembly slideably disposed in said shaft for selectively applying a compressive force to the crystal is used to kill weeds by impressing a voltage across the roots of the weed. An electrically conductive path is formed between one end of the crystal and ground. A second electrically conductive path is formed between the other end of the crystal and a probe adapted for insertion into the roots of a weed. When a compressive force is applied to the crystal, the voltage generated is passed through the root to ground to kill the root, thereby destroying the weed.

US5740627 -- Method and Apparatus for Enhancing Growth Characteristics of Seeds Using Ion-Electron Avalanches

Abstract ~ A method and apparatus for treating seeds with self-organized avalanches of electrons between electrodes (11, 12) as a cathode and an anode with seeds (13) between the anode and cathode or on the anode. Apparatus circuit (200) in a box (20) provides simultaneous DC and AC between the electrodes which creates the avalanche of electrons which project into the seeds. The seeds must be stored before planting. The seeds so treated have enhanced growth characteristics.

US5806294 -- Weed Electrifier

Abstract ~ A portable, hand held tool for trimming and electrifying vegetation. The portable, hand swingable, weed trimmer passes electricity through its cutting or trimming element so as to pass electricity into the weeds to kill the roots of the weeds. The tool includes a power unit for rotation of a cutter drive. A pancake generator generates electricity via rotation of the cutter drive. Brushes between the pancake generator and the cutter blade conduct current to the cutter blade, which in turn permits the current to pass into the vegetation as the cutter blade trims the vegetation.

US5819467 -- Method of Stimulating Plant Growth

Abstract ~ A conductive helical coil is spaced around the stem of a growing plant, and alternating current is passed through the coil to induce an electromotive force in the stem and stimulate growth.

US5868919 -- Method and Apparatus for Dissociating Materials

Abstract ~ An apparatus and method of use for dissociating materials includes a power supply, high energy capacitor, high energy trigger device and an probe and reactor arrangement for treating both solid and medium/media materials. A near instantaneous discharge of the electrical charge stored in the capacitor via the probe can be used to dissociate the material, either medium/media or solid, for a desired result. Hazardous materials can be treated to be rendered non-hazardous, rocks or other solid material can be treated for reduction in size, plant seeds can be treated to enhance plant growth surfaces of granular material can be scored or thermally polished and milk, juices and blood could be treated for sterilization.

US6023880 -- Method and Apparatus for Enhancing Growth Characteristics of Seeds Using Ion-Electron Avalanches

Abstract ~ A method and apparatus for treating seeds with self-organized avalanches of electrons between electrodes (11, 12) as a cathode and an anode with seeds (13) between the anode and cathode or on the anode. Apparatus circuit (200) in a box (20) provides simultaneous DC and AC between the electrodes which creates the avalanche of electrons which project into the seeds. The seeds must be stored before planting. The seeds so treated have enhanced growth characteristics.

US6055768 -- Apparatus for Electrically Charging Fluids

Abstract ~ The present invention relates to a method and apparatus to energize a fluid. In one embodiment, the apparatus comprises a housing defining a bore therethrough within which is disposed an antenna so as to define an annulus between the housing and the antenna, the antenna being electrically coupled to both the housing and an electrical power source so as to create an electrical field through which water or other fluids may be passed [to feed plants].

US6192622 -- Mobile Device to Eradicate Red Palm Weevils and Trees Stem Bore

Abstract ~ A high frequency power source (4) and (5) supplies electromagnetic waves (10-100 MHz) that are supplied to a single or a pair of plates that surround a trunk of the infested tree. The electromagnetic waves are used to kill red palm weevils and trees stem borers within the trunk of the tree. The plates are cylindrical, half cylindrical or flat, with insulated metal sheets that surround the trunk and upper roots of the infected tree.

US6237278 -- Method and Device for Weed Control

Abstract ~ Weed seeds are controlled by high voltage pulses with short duration which electropermeabilize the cell membranes of weed seeds in the ground. The device is selective and damages only germinating weed seeds and plants early in their life cycle. The required amount of energy is small; with rectangular pulses the optimal field strength is between 100-300 kV/m with a duration of (10-100 microseconds). A transformer placed on a sowing machine transforms electrical energy to high voltage pulses. The energy may be taken from the pulling tractor via a transmission or from an integrated power source. The high voltage pulses are applied to electrically conducting via applicators to two or more fixedly spaced plates to the soil around newly sown seeds.

US6539664 -- Method and Devices for Treatment of a Biological Material with a Magnetic Field

Abstract ~ A device for the manipulation of a biological material [seeds] by a magnetic field is presented. The device comprises a magnetic field source coupled to a current source. The current source is of a kind supplying an electric current of at least two electrical degree shifted phases. The magnetic field source comprises a two-part inductor, each inductor part producing a coordinate varying magnetic field (CVMF). Each inductor part is formed by at least two conductors aligned in a spaced-apart relationship, wherein each of the at least two conductors is connectable to a different phase of the current source, and has two spaced-apart parts arranged such that when the conductor is connected to the current source, the electric current flows in its two parts in opposite directions, respectively. The conductors of each inductor part are arranged such that each two locally adjacent conductor parts are associated with two different phases of the electric current source. A distance between the two conductor parts coupled to the same phase of the current source defines a half-wavelength .lambda./2 of a wave of magnetic induction of the CVMF. This distance is selected in accordance with a predetermined relation between the wavelength .lambda. and an effective space .DELTA. within the magnetic field region defined by the dimensions of the biological material and its distance from the magnetic field source.

US1268949 --- Method & Apparatus for Agricultural Engineering

US1952588 -- Apparatus for Generating & Applying Electrostatic Energy

US3559337 -- Apparatus for Electroculture

US1737866 -- Method of and apparatus for the practice of agriculture

US2007383 -- Apparatus for and method of electrically treating soil

US1874207 -- Plant bed

US882699 -- Electrical Receptacle for Plants

US1331261 -- Means for treating plants

US2588561 -- Apparatus for electrically treating the soil

US2682729 -- Electric weed killer

US2876586 -- Attachment for an agricultural implement

US3559337 -- APPARATUS FOR ELECTROCULTURE

US3623265 -- METHOD OF FIXING NITROGEN IN THE ATMOSPHERE AND THE SOIL

US2308204 -- Means for Affecting Plant Life Processes

US2735226A -- Method and Apparatus for Treating Cotton Seed

US3675367A -- Apparatus for magnetically treating seeds

US4188751A -- Magnetic seed treating device

GB2189673 -- Exposing Seeds to a Magnetic Field

DE1931449A1 -- Method and device for treating seeds

US3765125 -- Device for Treating Seeds

Abstract -- Apparatus for treating seeds to induce magnetism in the seeds including a hopper for containing a quantity of seeds to be treated, a conveyor for conveying seeds from the hopper, a tubular conduit having its inlet end disposed to receive seeds from the discharge end of the conveyor and its outlet end diposed below the inlet end. Radiant energy means is supported above the conveyor for exposing seeds being conveyed by the conveyor to radiant energy prior to discharge of the seeds into the inlet of the tubular conduit, and a magnet is supported on the tubular conduit for producing a magnetic field within the conduit. Agitating means is provided in the conduit for varying the orientation of seeds passing through the conduit with respect to the magnetic field.

GB102081A -- Improvements in the Treatment of Seeds

Abstract -- Seeds, before sowing, are steeped in natural mineral waters containing nitrogen, chlorine, and other gases and small quantities of metallic salts. When cereals are being treated, a current of electricity in the proportion of 3/4 ampere per 10 gallons of the water may be passed. After steeping, the seeds are sprinkled with petroleum or dried in a drying-machine or hot room.

GB262052A -- Method of utilising atmospheric electric currents and electric earth currents for the promotion of plant growth

GB1065864A -- A disintegrable permanent magnet for use in the soil

Abstract -- A permanent magnet moulded with a water-soluble binder is embedded in soil to accelerate plant growth. It then disintegrates to a powder in the presence of water to act as a fertilizer. The magnet may be of iron, Co-Fe ferrite, or Mn-Bi alloy. A deliquescent material, e.g. Mg, Ca, or Fe chloride, may also be incorporated.ALSO:Plant growth is accelerated by use of a permanent magnet moulded with a water-soluble binder, which disintegrates in the presence of the water in the soil. The magnet may be of iron, CoFe ferrite, or Mn-Bi alloy. A deliquescent material, e.g. Mg, Ca, or Fe chloride may also be incorporated. In the experiments described, the growth of radishes and lettuce was investigated with and without magnets, and with the magnet at different depths in the soil. A citrus grafting was also carried out.

JPS6024121A -- Enhancement of productibity of animal and vegetable

FR2579412A1 -- PROCESS FOR TREATING PLANTS AND CONTAINERS FOR CARRYING OUT SAID METHOD

Abstract -- The invention relates to the treatment of plants planted not in open earth but in a lump of earth placed in a container such as a pot 1-2. The container according to the invention is characterised in that it is impermeable and combined with at least one permanent magnet 4 placed on the base 2 and having no contact with the side wall 1.

GB2145317 -- METHOD FOR PROMOTING THE PRODUCTIVITY OF ANIMALS AND PLANTS

Abstract -- A novel method to promote the productivity of animals and plants is disclosed, which comprises irradiating animals and plants with an effective amount of an alternating magnetic line pulse of force having a waveform similar to that of diphasic action potential, magnetic potential of 10-100,000 ampere turns, pulse width of 1/500-1/50 seconds, and pulse intervals of 1/100-1 second. With the practice of the present invention, the yields and qualities of animal- and plant products, such as meat, milk, egg, fur, coccon, pearl, plant stem, flower, fruit, mycelia, antibiotic, enzyme and biologically-active substance, are remarkably improved.

JP4705075 -- WATER PURIFIER… IRRIGATION AND SPRAY SYSTEM FOR AGRICULTURE…

PROBLEM TO BE SOLVED: To provide a technique suitable for use in an electrolyzed water producing apparatus that can efficiently produce weakly acidic or weakly alkaline electrolyzed water. SOLUTION: The electrolyzed water producing apparatus 10 includes: an anode chamber 20 equipped with an anode electrode 22; a cathode chamber 30 equipped with a cathode electrode 32; an intermediate chamber 40, provided between the anode chamber 20 and the cathode chamber 30 for storing an aqueous electrolyte solution, an anion exchange membrane 24 for partitioning the anode chamber 20 and the intermediate chamber 40 from each other; and a cation exchange membrane 34 for partitioning the cathode chamber 30 and the intermediate chamber 40 from each other. The anode chamber 20 and the cathode chamber 30 are in communication with a communication hole 52 provided on a partition wall 50. The electrolyzed water producing apparatus 10 is preferably applied to apparatuses in which sterilization is necessary, for example, water purifiers.

Agricultural Research ( Feb. 2003 )

Radio Frequency Puts the Heat on Plant Pests

To prevent influx of pests that could create agricultural problems, produce-importing nations enforce strict rules --depending on the commodity and the infesting insect. The rules often require vulnerable produce to be treated in some way that ensures destruction of pests.

For several decades, methyl bromide has been a mainstay treatment to kill a wide array of quarantined pests as well as those encountered in orchards, packinghouses, and food plants. But this potent chemical fumigant is being phased out because of evidence linking it to damage to Earth's ozone layer.

Although the effectiveness of using radio waves to kill destructive insects in agricultural products has been known for 70 years, the technique has never been applied on a commercial scale. A recent cooperative effort by four ARS research laboratories and two universities aims to overcome the technical barriers for the use of radio wave heating to control pests on a commercial scale.

Electromagnetic waves of radio frequency can make molecules vibrate and heat up --like microwaves heat food. The trick is to kill pest insects without killing the taste or texture of the food they infest.

Since 2000, a team led by Juming "Jimmy" Tang of Washington State University (WSU) in Pullman, involving four ARS laboratories and the University of California-Davis (UC-Davis), has been working on a 4-year study to see whether radio waves would be an economical, environmentally friendly alternative to methyl bromide and other chemicals to effectively rid fruits and nuts of live, quarantined insects.

In Texas -- It's Chiefly Citrus

In Weslaco, Texas, ARS entomologist Guy J. Hallman is checking out use of radio frequency treatment of citrus against the Mexican fruit fly. He's in the Crop Quality and Fruit Insect Research Unit at the Kika de la Garza Subtropical Agricultural Research Center. Hallman is developing a device to simulate what's needed to heat-treat citrus fruit with radio waves commercially.

"We're trying to bridge the gap between the laboratory and real world," says Hallman. "Once we know how to treat fruit in a commercial situation and how much it will cost, any producer, shipper, or packinghouse operator can use the information to decide whether radio wave pest control is a viable option."

In Hallman's system, citrus fruit would pass through a conveyor between a series of radio frequency heaters. To simulate a commercial system in the laboratory, the fruit are conveyed in a circulating water bath to keep them moving during heating. This would prevent the fruit's overheating from extended contact with any one area of the bath. And to ensure continuous heating from the peel in to the fruit's center --essential to killing all fruit flies that might be present-- a bumper would dunk any fruit that bobbed above the water surface. This prevents dark-black rings from forming around the fruit at the water's surface because of an energy concentration where the water meets the air.

A method using just hot air to treat fruit in boxes or bins has been tried commercially in Mexico with mixed results. It takes hours to complete and puts a strain on the fruit's skin, sometimes causing heat damage. Radio frequency heating can be done in less than half an hour and is less damaging, since the fruit is heated uniformly throughout.

Hallman has focused on grapefruits but is also working with other citrus, including oranges and tangerines. The larger the fruit, he notes, the harder it is to heat uniformly and the more likely to form hot and cold spots.

"This multi-lab project is making a serious effort to take a look at things that haven't been looked at with radio frequency heating," says Hallman. "I think we stand a good chance of finding out how radio frequency disinfestation can be done to a large volume of fruits or nuts -- and if it can be done on a commercial scale." He predicts that by this summer he'll have a good idea of what the treatment will cost.

In Washington -- Apples and Cherries

If you're in Wapato, Washington, don't be enticed by the apples floating in the tub in James Hansen's laboratory. You don't want to go bobbing for them.

There are several reasons, says Hansen, an entomologist with ARS' Yakima Agricultural Research Laboratory. The first is that this particular tub is filled with salt water. Second, if you were to latch onto one of the apples with your teeth, you might bite the proverbial worm-- a larva hatched from a codling moth egg.

And Hansen wants these apples intact -- no tooth marks, please. Such a mark might skew the results of tests he is conducting on use of radio waves to rid the fruit of live, pesky insects like the codling moth before market -- or shipment to trading partners like South Korea and Japan, where such pests might not already occur. Japan is particularly stringent about what phytosanitary methods it will accept for disinfesting fresh produce.

This rule also applies to sweet cherries, a tree fruit commodity that generates over $145 million in yearly national export sales, notes Hansen. In cooperation with the team led by Tang, a professor in biological systems engineering at WSU, Hansen plans to "bathe" tubs full of apples and cherries with radio waves to determine exposure times that will kill codling moth larvae without affecting fruit quality.

From two lines of research, one focusing on the insects, the other on fruit quality, and three major disciplines -- engineering, entomology, and plant physiology -- the collaborators hope to position radio wave treatment as a technology that can be readily adopted by commercial packinghouses or quarantine operations in lieu of methyl bromide.

"Without suitable alternatives to methyl bromide, we're going to be up a creek," ARS horticulturist Stephen R. Drake says of the U.S. fruit industry's fight against quarantined pests. He is with ARS' Tree Fruit Research Laboratory in Wenatchee, Washington.

"Ideally, you want to treat the fruit with radio frequency while it's being packed and designated for a particular market," Hansen explains. "Commercial packers can't afford to have produce sitting there, so we want this treatment to kill the insects as soon as it can."

Tang, Hansen, Drake, and Lisa Nevens, an ARS entomologist at Yakima, first began working on the radio frequency project in 1996.

In California -- Tree Nuts and Dried Fruits

Meanwhile, in California, entomologist Judy A. Johnson is also keenly attuned to the potential of radio frequency energy to zap destructive insects. Her primary targets? The wiggly larvae of the navel orangeworm, Indianmeal moth, and codling moth. These insects are among the worst enemies of walnuts, almonds, and pistachios and of dried fruits such as figs and raisins. Johnson has newly added red flour beetle to her list of culprits-- a lesser pest of the nut and fruit crops but a major problem in flour mills and food-processing plants.

Johnson is doing the radio frequency work at the ARS San Joaquin Valley Agricultural Sciences Center at Parlier, near Fresno, in close association with cooperators at WSU and UC-Davis. They have already developed a preliminary picture of the target insects' ability to endure heat-- their "thermal tolerance."

The laboratory experiments that Johnson and her ARS and university colleagues conducted are the first to extensively detail the thermal tolerance of the navel orangeworm, Indianmeal moth, and codling moth.

For one test, Johnson and co-investigators drilled tiny holes in over 500 in-the-shell walnuts; enticed the slender, whitish navel orangeworms to enter the shells; then plugged the holes to block the insects' escape. The scientists then tried some novel combinations of radio waves and hot forced air, that is, air that's heated and blown into the test chamber holding the nuts. Radio waves, alone or combined with hot forced air, were used to heat the nuts to 55° C (131° F) in about 5 minutes. Hot forced air was then used to keep the nuts at 55° C for 5 or 10 minutes.

"All the treatments killed 100 percent of the navel orangeworms," reports Johnson. What's more, tests led by co-researchers Tang at Pullman and Elizabeth J. Mitcham at UC-Davis, showed that the treatments didn't harm the quality of the nuts -- even in long-term storage.

"That's critical," Johnson points out, "because walnuts are often stored for a year or more before they show up at your supermarket."

In addition, walnuts are rich in oil, so they're more vulnerable to heat damage than some other kinds of nuts, such as almonds. "That's why we think that if a treatment is okay for walnuts," Johnson continues, "it will likely be okay for almonds."

Indianmeal moths proved to be more susceptible to heat than navel orangeworms are. "Indianmeal moths are silvery, and wedge-shaped. If you open a kitchen cupboard where you keep raisins or breakfast cereals and a little moth flies out at you," Johnson explains, "chances are it's an Indianmeal moth."

For this experiment, Johnson and her colleagues used metal heating blocks, or plates, specially designed by Tang for the radio frequency research. They placed target insects in the small gap between the plates, which were then heated to specific temperatures and held at those temperatures for precise periods.

She and her associates assembled some 15,000 Indianmeal moth larvae for the study, exposing them to temperatures ranging from 44° C to 52° C (about 111° F to 126° F) for 2 to 100 minutes. "In general," Johnson comments, "the lower the temperature, the longer it took to kill the larvae. These readings are the basis for a new, math-based model for projecting the rate of kill at other time-and-temperature regimens. Because of the large number of larvae tested and the range of temperatures that we investigated, we're very confident of the accuracy of the model's projections."

Johnson and her cooperators also used the special heat

plates to discover more about the amount of time and heat that

it takes to kill navel orangeworms. They exposed 15,000 navel

orangeworms to temperatures ranging from 46° C to 54° C (about

115° F to 129° F) for 1 to 120 minutes. Using the new data,

they created a mathematical model of the navel orangeworm's

thermal tolerances.

HIERONYMOUS, Thomas G. Cosmiculture

Electrolyzed Water

http://en.wikipedia.org/wiki/Electrolyzed_water

Wikipedia

Electrolysed Water

Electrolysed water (EOW also known as electrolyzed oxidizing water, electro-activated water or electro-chemicaly activated water solution) is produced by the electrolysis of ordinary tap water containing dissolved sodium chloride.[1]

Creation process